The following blog post was written by Gabrielle Anderson, Spark-Y Sustainability Educator,

on our Spark-Y school program with Crossroads Elementary Inquiry Zone.

Elementary schoolers have the best ideas. This spring at Crossroads Elementary, the ideas have been freely flowing. We always encourage creativity and discovery in the Inquiry Zone, Spark-Y’s realm of enlightenment at this school (a.k.a. where we carry out our programming); one of the expectations posted on the wall is that I won’t always give them the answer. So these 3-5 graders are accustomed to challenges that stretch their young brains. Lately, they have been putting those warmed up muscles to the test with some problem-solving challenges.

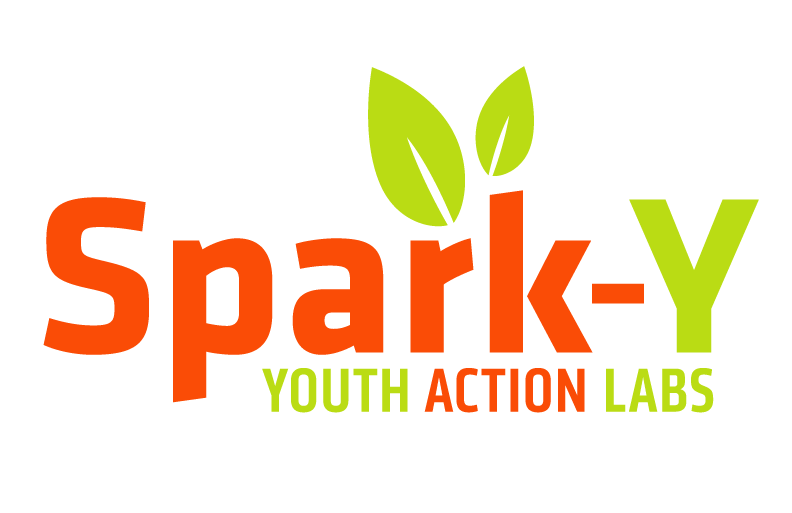

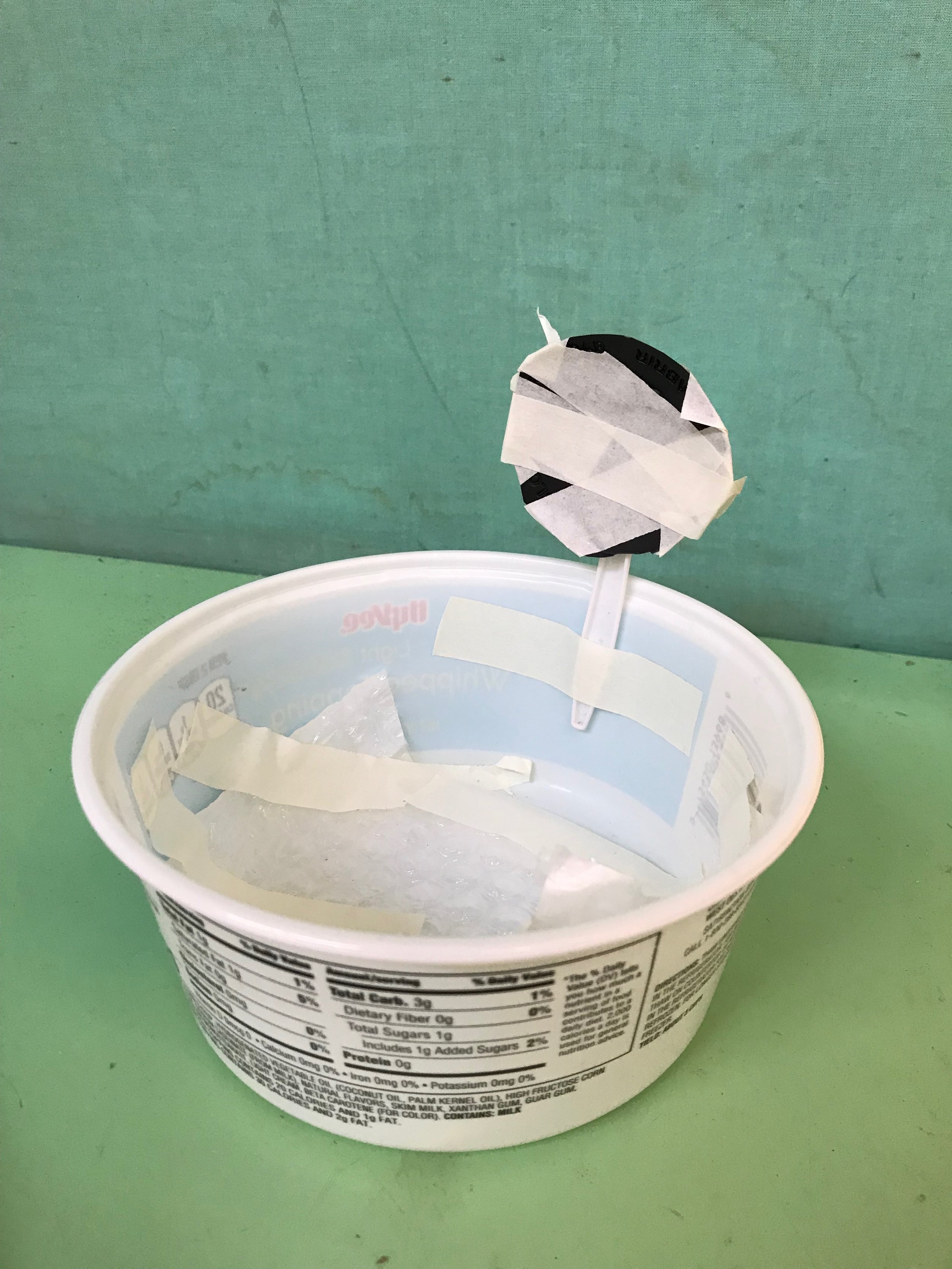

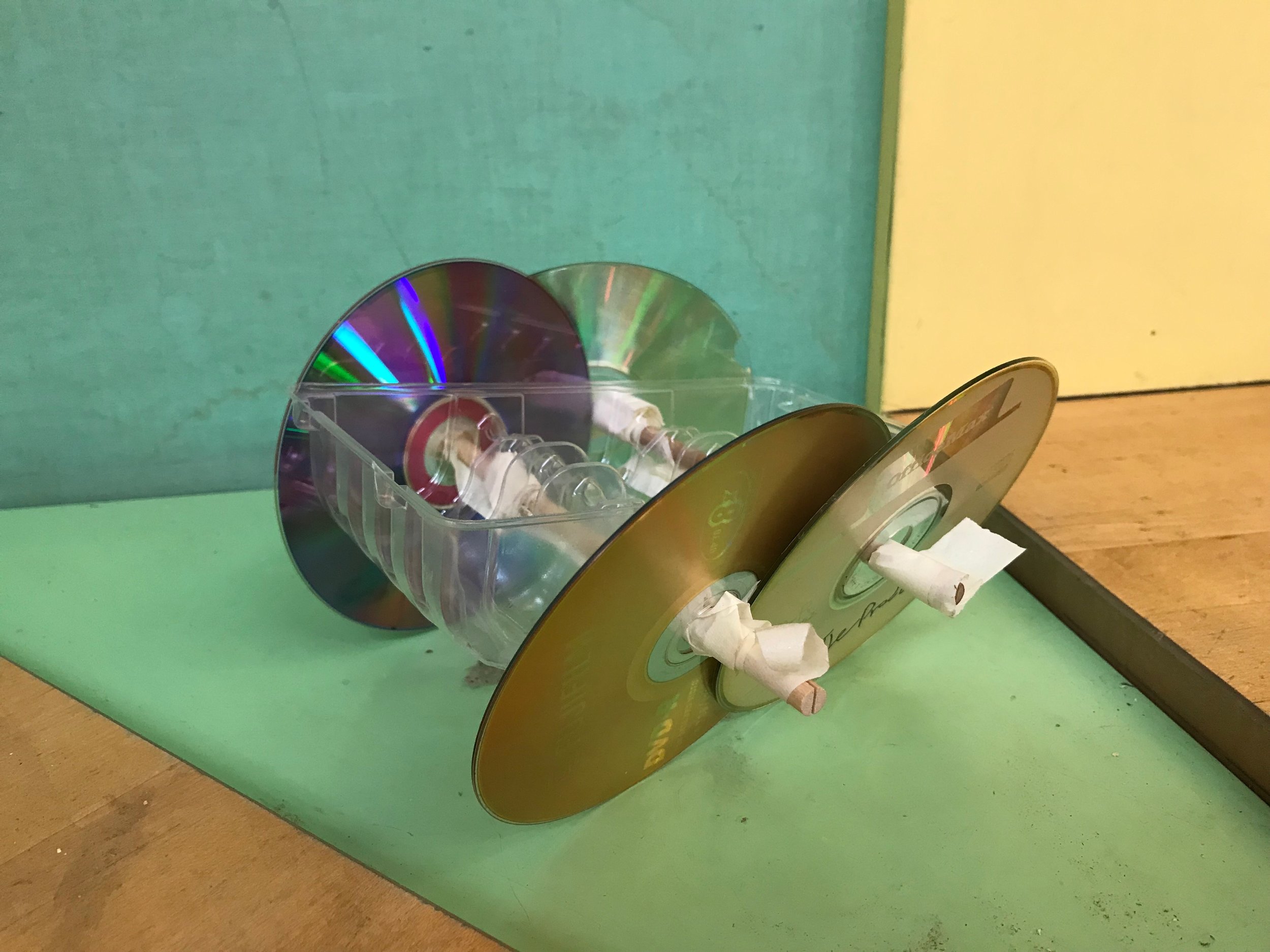

Third and fourth graders are currently focusing on engineering, using trash as a material. At three different stations, students are presented with a pile of waste materials and challenged to build a boat that can stay afloat when piled with pennies, a bridge that can withstand the pressure of a stack of books, or a car that can speed down a ramp and across the room. I have seen boats built out of jar lids, aluminum foil, and straws that can hold 70 pennies! There have been cardboard bridges that can hold 30 books! And the cars - well, the cars could use some improvement. Wheels are hard. These kinds of challenges inspire the kids to experiment, test, and rebuild.

Another batch of great ideas came about recently when I was teaching a lesson about the Engineering Design Process. I presented them with a problem: Because of the shape of the Inquiry Zone, I cannot see all the students at the same time. This makes it difficult for me to know when students need help. What could we build to solve this problem? A few ideas were thrown around. We could install buttons that illuminate lights to show that someone in that area needs help. We could have more teachers in the I-Zone to help (if only!). We could knock down the walls. After a vote, students decided that the best plan was to install a bell system, so if a student needed help, they could pull a string that would ring a bell and alert the teacher of their need. Brilliant! When we concluded the lesson and moved on, one student asked, “Wait, we aren’t actually going to do it?” Maybe now we will.

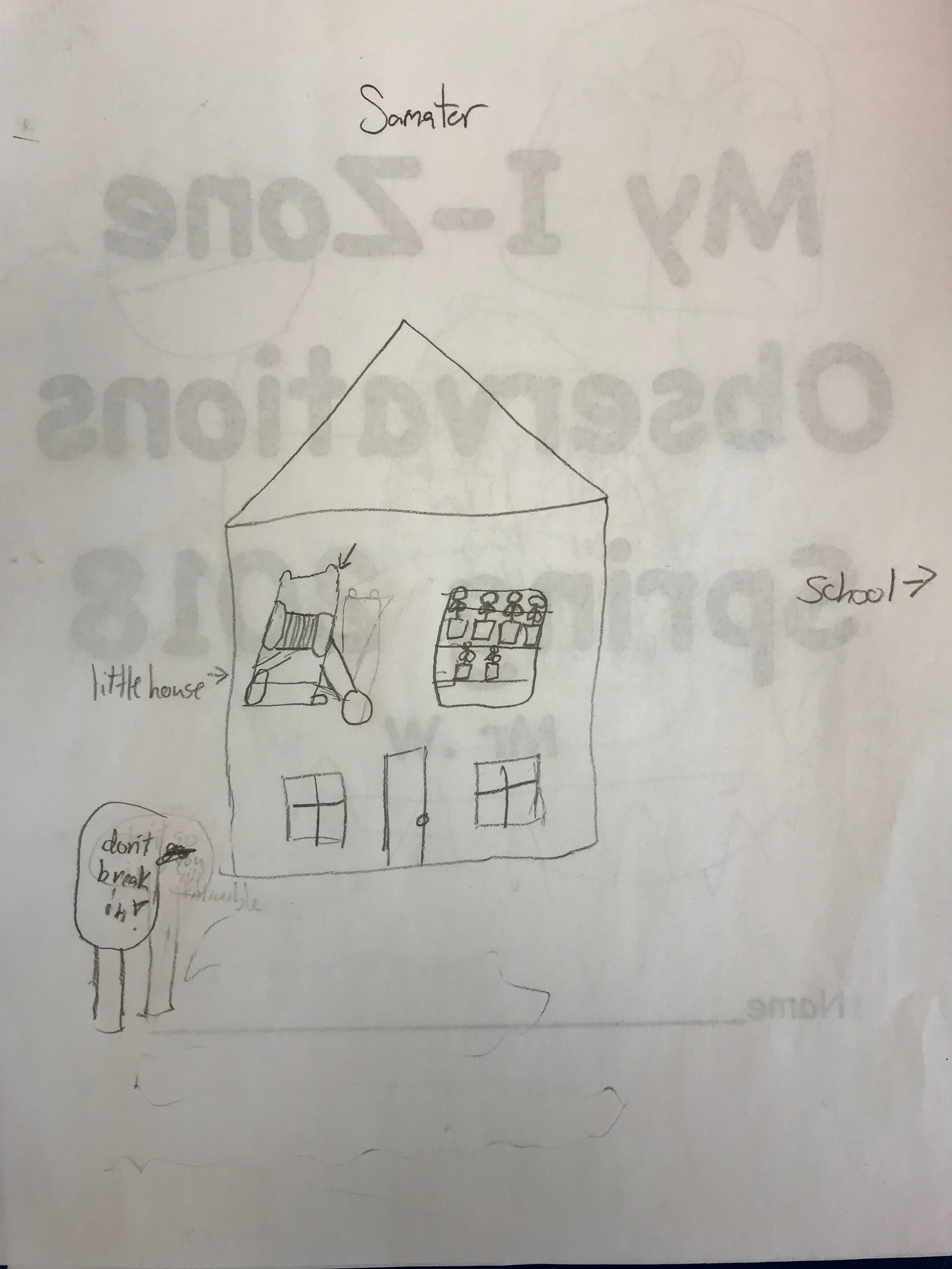

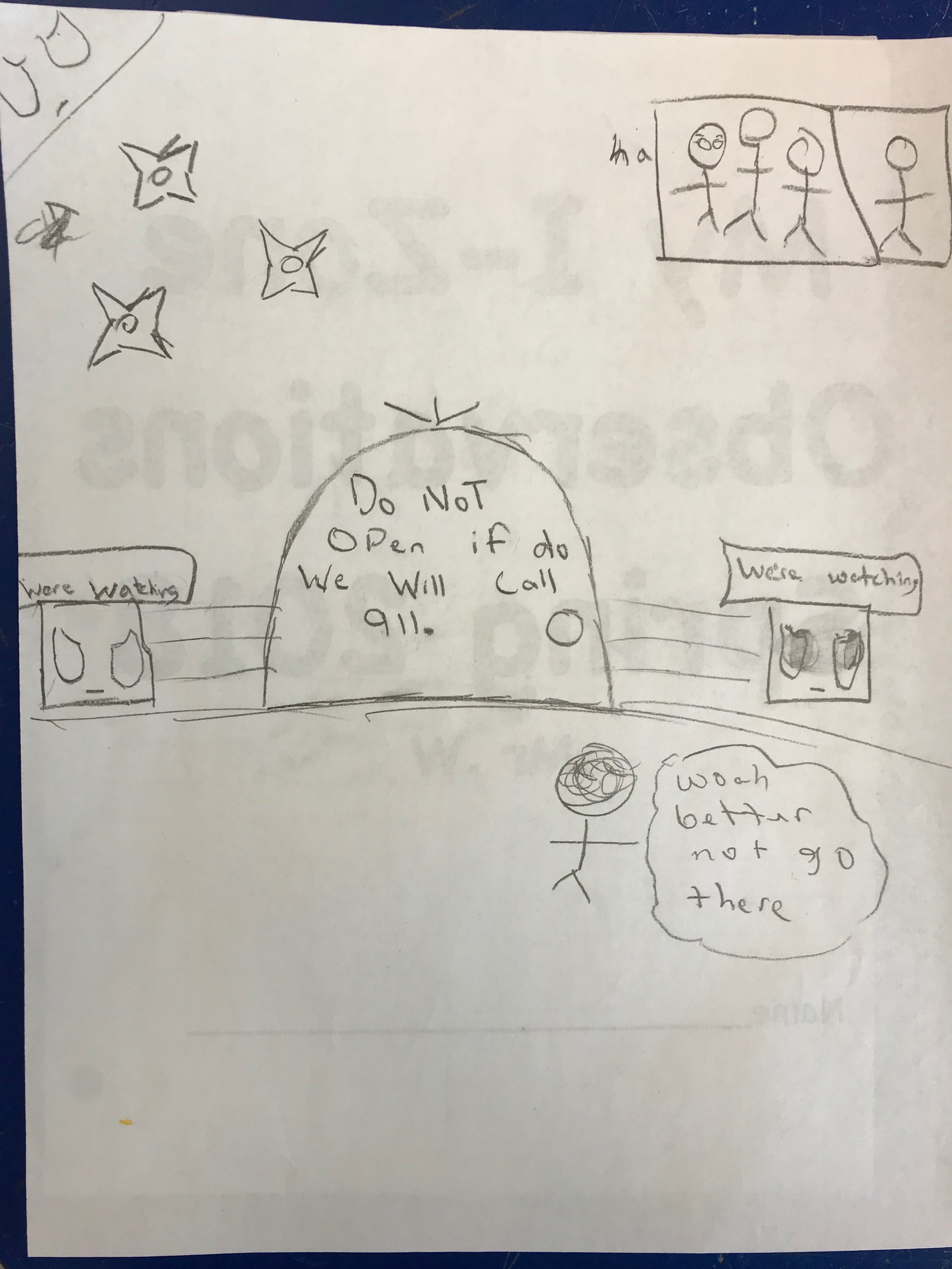

Crossroads Ambassadors have also been brainstorming. The Ambassadors are given the responsibility of helping make Crossroads more sustainable, spreading the word about the I-Zone, and generally being stewards of their school community. This spring, they plan to build a structure that protects the garden hose. The hose cannot stay outside all of the time for fear that it will get stolen or broken, but that makes watering the garden in the summer a huge hassle, which in turn has prevented the gardens from really flourishing in the past. The plan is to build a durable structure with a lock so that water access is simple and efficient.

Ambassadors drew up designs, with all types of security features and fun details. There are plans for 24 hour surveillance, alarms, and guards to protect the precious garden hose. Of course, these plans will be dialed back and grounded in the realities of budget and time. But other ideas were totally doable: making the structure look like a little house, or painting signs that say a ghost lives there to scare away potential burglars.

Though all of the Ambassadors’ hose house dreams may not come true, working within limitations is an important part of the design process. Besides, it is fantastic that their original designs were lofty, without considering the restraints of money, time, or available resources. I would rather they dream big and scale back than fail to dream at all.

The same can be said about all of the challenges Crossroads kids face in the Inquiry Zone and beyond. If they feel comfortable facing problems and thinking of creative solutions, they will have an easier time facing adversity and making change throughout the rest of their lives. The Inquiry Zone and Spark-Y’s programming there give students a unique space to play and experiment without being told their answer is right or wrong. There are no grades or tests. This environment fosters that freedom to dream big and be creative, which I truly believe is building up the leaders and change-makers of tomorrow.